The latest news on the ecu re-mapping front, is that we finally have the software that allows us to map the 2021 Yamaha R1.

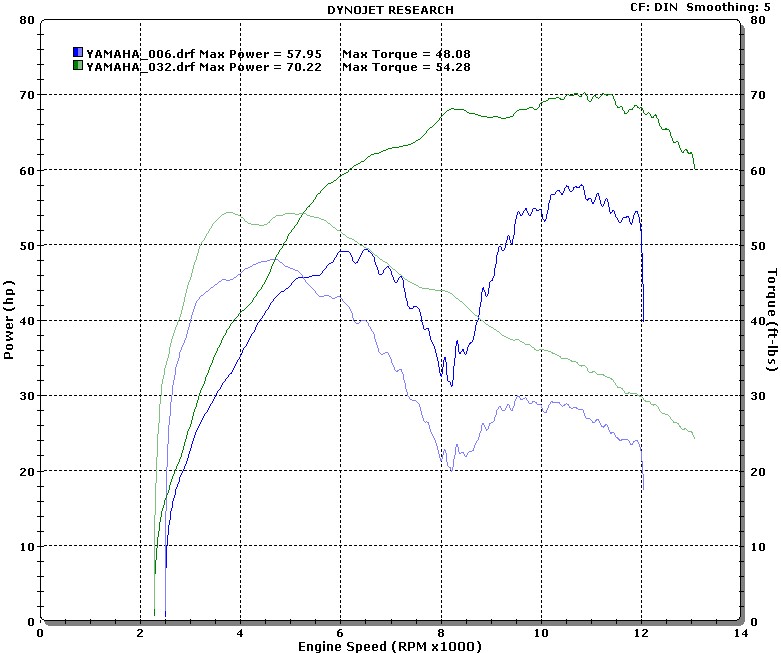

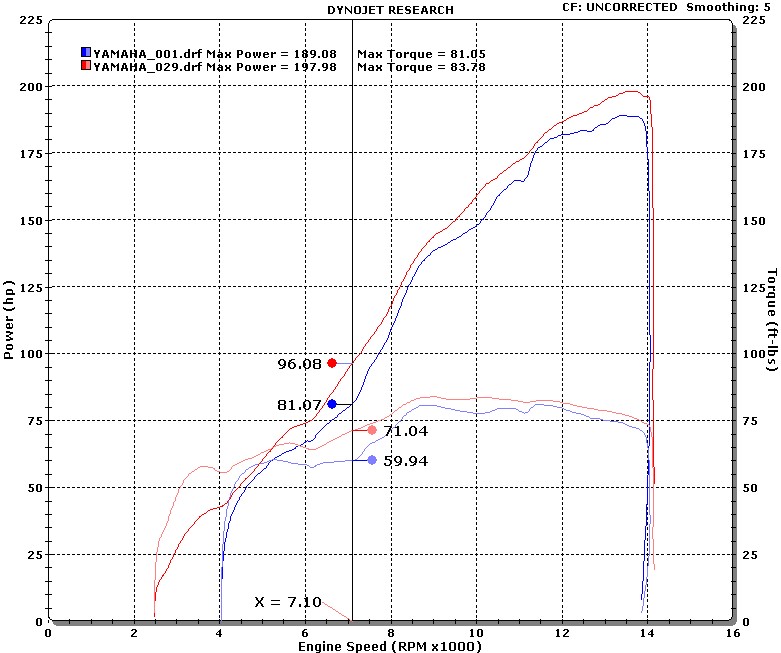

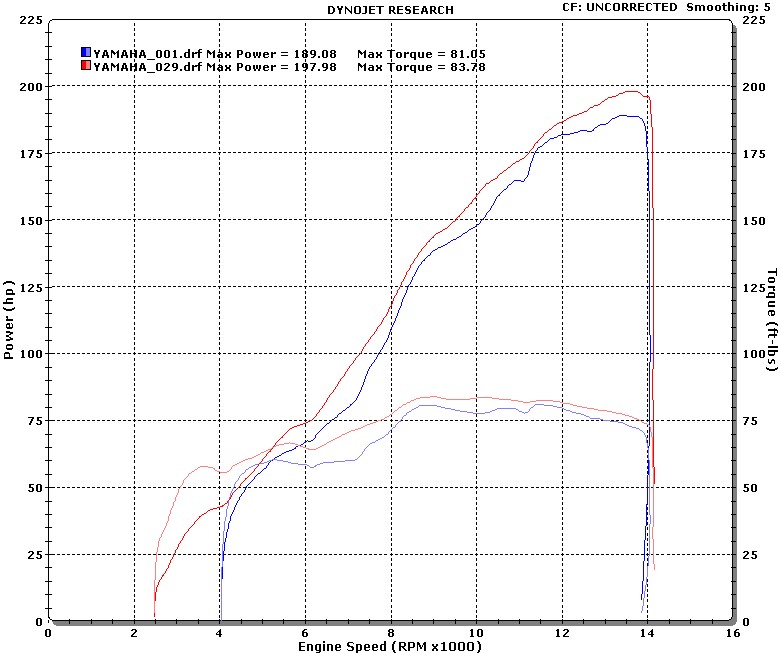

As you can see by the dyno graphs attached, Andy has shown the max power gain at 30% throttle along with the gain at max power.

Dyno Tuning &

ECU Reprogramming

BSD Performance uses a Dynojet 250i

Load Control rolling road Dynomometer

The ability it gives, to control engine rpm at any throttle opening, is crucial for consistency and the precise build of a performance fuelling map. Ironically, the knowledge earned in the pre-fuel injection era, working on the dyno with CV and flat slide carburettors has proved an invaluable foundation for everything we do with EFI.

When a bike goes on our dyno the first thing that happens is that it’s strapped down correctly – this is very important. Next, we check the engine oil level, rear tyre pressure and position of the bike. A connection is made to the ignition system to get an rpm reading and we plug our Lambda sensor into the exhaust (if available) or use the ‘Sniffer’ to read the exhaust gases.

The bike’s then brought up to running temperature, usually under load to make sure the engine’s fully stretched and ready to work. The fans then go on to control the engine’s temperature and add airflow into the airbox. A Power Run is made; this consists of a roll-on from around 2000rpm revving feely, and again under load. After three or four Power Runs the engine’s performance will drop off and, assuming a constant temperature, has peaked.

At this point we stop and analyse the power, torque and air/fuel ratio, assessing the engine’s performance as stock.

If necessary we’ll perform some part-throttle runs. This needs another connection to the Throttle Position Sensor (TPS) via the analog channels on the dyno, and after adjustment allows us to ‘read’ TPS, dial in an actual throttle position and do a run. This is perfect for identifying fuelling/ignition flats spots or glitches in the power delivery; and large numbers of today’s bikes are cluttered with emission control units that cause small-throttle opening and bottom-end running problems.

Many of our customers, road or race, fit free-breathing exhaust cans or full systems and are after horsepower and torque gains; we recommend fitment of a suitable after-market air filter at the same time to save doubling up of dyno time. With these changes an engine’s fuelling will definitely need work and we offer two routes for our customers to take, either with Power Commander or our ECU Reprogramming Service.

Power Commanders are a relatively easy fitment; disconnect the injector wires, connect in the PC and earth it to the battery. The work for us lies in looking at the fuelling on a part throttle run and then, via Tuninglink (a piece of software on the dyno, which puts the Power Commander in a closed loop with the Lambda and computer) analysing and adding the ideal air/fuel ratio. This builds a basic map, but what works on the dyno does not necessarily work on the road…

And this is where our experience and detailed knowledge make a tangible difference; we go back and manually ‘trim’ at small, less than 40% throttle openings, where the bike spends most of its life. Once we’re happy that what we have on the dyno will suit the customer’s requirements, the bike is ridden on a 10-mile loop that includes a mixture of fast and very slow corners, to assess its performance in the real world at a variety of road speeds, engine rpm and throttle openings.

BSD Performance has a great deal of experience

working with Dynojet’s Power Commander system

And many others, such as Yoshimura’s EMS and Nemesis. All offer options, but we’ve found in the last few years that many customers with stock (or lightly modified) road bikes have asked us to solve issues for them. Most can be traced to Euro 3 legislation, as all modern motorcycles are fitted with emission and noise controls that effectively handicap output and hinder power delivery, in some way or other.

By far and way the most elegant way of solving these problems is to work directly on the engine’s stock Electronic Control Unit (ECU). The system we now have allows us to ‘talk’ directly to the ECU and make changes – including switching off the Lambda sensor (which manages the fuelling to safeguard the exhaust catalyzer and reduce emissions). Lambdas also contribute to on/off throttle snatchiness at low rpm thanks to the lean running condition they create.

Many bikes have ‘noise flaps’ fitted in the exhaust, which only open at higher rpm. These too cause hiccups in power delivery and we can turn them off too, as well as dealing with any restrictions the manufacturer has built in through the lower gears (the Ducati Streetfighter, for example is restricted to 60% of its full power in first, second and third).

Essentially, our ECU Reprogramming service delivers a bike engine as the manufacturer designed it originally; after a Dyno run to establish baseline performance we suck the stock map out, switch off anything we feel that’s causing a problem and then re-map taking account of any changes made (air filter/exhaust etc). We can also check and turn off fault lights. The new performance map is then uploaded back into the ECU and the bike checked on the Dyno.

BSD Performance offers a cost-effective, wire and bolt-on free ECU upgrade for anybody that’s unhappy with their stock bike or who has fitted cans and not made any of the necessary adjustments. We can also make engines much more economical if needs be – perfect for the long distance or adventure sports rider.

Our ECU reprogramming service caters for BMW, Ducati, Triumph, KTM, Moto Morini and Moto Guzzi. We can also work on late-model Aprilias and will be adding new models – including the BMW S1000RR and key bikes from Kawasaki and other manufacturers – in time. The stock, original map is kept securely on file and can be supplied to the customer via email, along with a jpeg dyno graph that reflects the engine’s performance stock, and after the ECU reprogram.