The reason we started to develop a gearbox specifically for GSX-R engines used in car chassis is that the choices – close ratio or standard – were obviously tailored to motorcycles. And because we got involved, quite early on, tuning GSX-R lumps for car use (track or road fun) it soon became obvious that the gearbox was one of the weak links, with the drive dogs often breaking or snapping and getting meshed in between the gears – destroying not just the gears but also the cases… that and the lack of ratio choice was enough to make it worth while doing something ourselves.

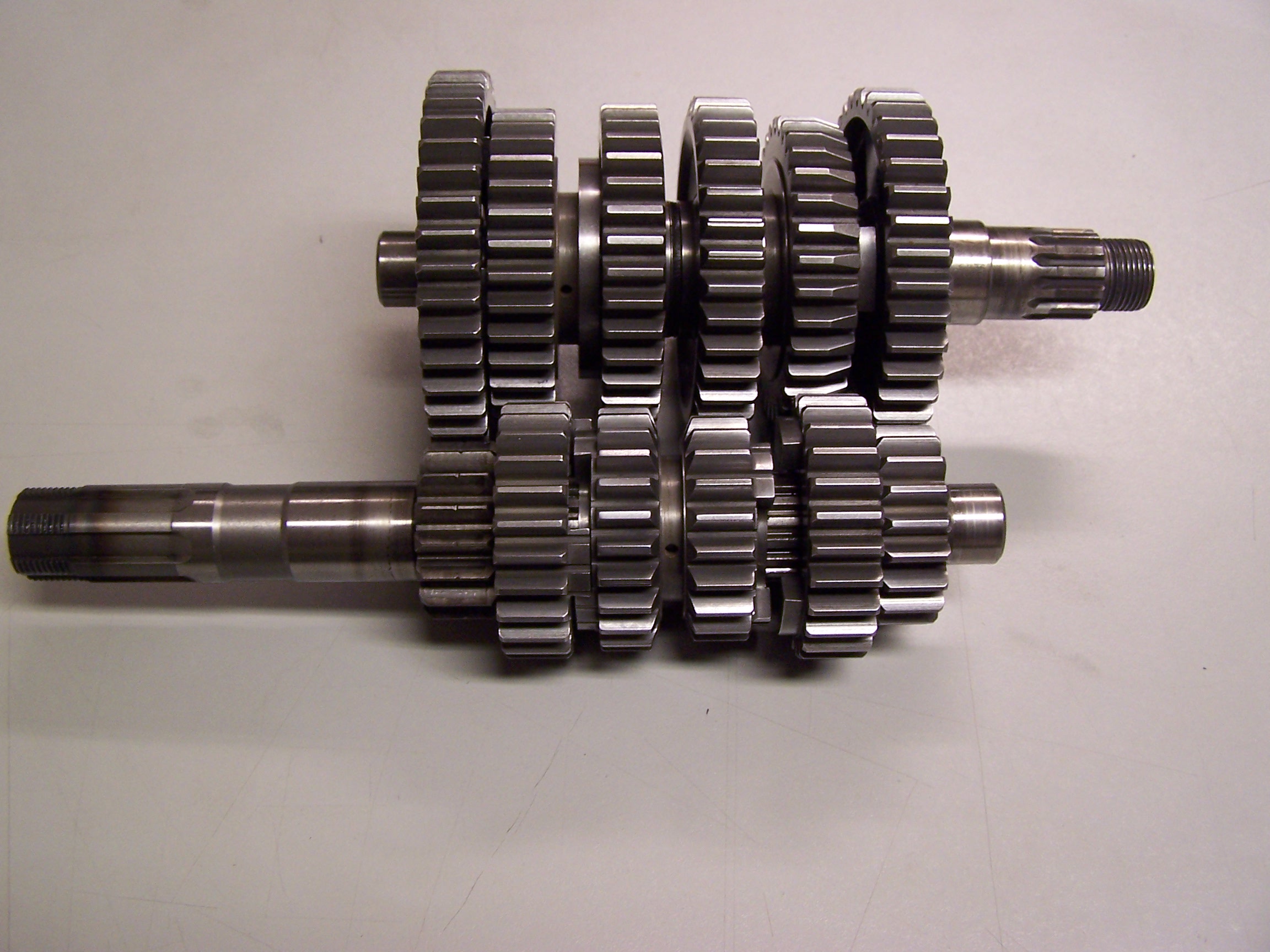

So with all the destruction we were witnessing we decided to (in-house) construct our own heavy duty BSD gearbox, using really good quality certificated EN36 base steel. We also changed the dog arrangement from the standard Suzuki design, away from what works in a two-wheeled application to what’s suitable for four. Saving weight isn’t the issue – it’s about reliability under load and spreading that load around a greater surface area.

Our gears are slightly heavier to deal with it, and are finished with a stone material prior to hardening and re-finished after which leaves them smooth but still with sharp edges (very important). The whole gearbox is not super-finished (where a brand new gear goes in a rumbler with a grinding paste, effectively taking 10,000 miles off it) which is great for limited-life race use, but not so good for the road.

If you’re interested give us a call or email for prices and specifications.