Trevor Franklin, Chief Road Tester for MCN, bought his longterm test KTM 990 SMT to us for an ECU sort-out and full set-up on the Dyno. As a stock motorcycle he found the big V-twin very snatchy at small throttle openings and tricky to ride in on/off throttle situations, and in an attempt to help the situation had fitted a Remus exhaust system, thinking that the road legal cans and catalyzer were strangling the engine.

Trev's big Katoom as it arrived pre-fettle, ready for its ECU to be unpicked and put back together...

The exhaust swap had no real positive effect however, which is why Trev made his way to us, as we can plug directly into the KTM’s ECU and deal with the problems. On the Dyno, the bike’s issues aren’t really noticeable – on the road, they were very obvious. It was horrible; off throttle, when you went to feed in a little power the motor simply wouldn’t pull cleanly, and there was a very direct open/closed feel when you rolled off and on the gas. Very awkward in damp conditions and simply not fun at all…

We’ve had a lot of experience with fuel injected bikes over the years, and know that the lambda sensor (situated in the exhaust, its job is to monitor the spent gas and adjust fuelling to suit pre-set parameters) has a big hand in all of the above symptoms, so the first job is to eliminate the lambda completely (this can be done on bikes with cats still fitted, but needs a slightly different approach for fuelling). As Trev’s KTM no longer had its cat onboard, thanks to the Remus system, we could simply switch off the lambda at the ECU. The secondary air system – essentially a slightly devious method that the manufacturers employ to ‘lean’ out the dirty exhaust gasses for emissions testing purposes – also needed disabling, so we could get a true measure of how the engine was fuelling with our own lambda sensor plugged into our computer via the Dyno.

Having dealt with both, we could then get on with remapping the bike’s ECU via our ReXxer, computer and Dyno. Now one of the problems with the big KTMs is that they use a MAP sensor (Manifold Air Pressure) to control the fuelling off the bottom at small throttle openings – at a certain rpm the ECU then switches over to a main fuelling map. There are two on the KTM, one for each cylinder, and these too contribute to the snatchiness so obvious at low rpm. This is what KTM has had to do to get their engine through the emissions tests; it doesn’t make it much good in the real world, though.

On the Dyno, we remapped the MAP tables, and the main fuel tables individually per cylinder. We also remapped the secondary butterfly valves which open progressively as per the ECU, at lower rpm and even shut down a little in the higher gears, to open fully at a lower rpm. This also helps deal with the cruising speed hesitation we felt on the road test, as at small throttle openings in higher gears the secondary butterflies are in full operation.

We also raised the rev limit by 300rpm, from 9,200rpm to 9,500rpm; a conservative, but useful margin of extra top-end power to play with. We could have made some ignition adjustments too, but in this case decided against it because out-and-out performance wasn’t the aim – what Trev wanted was the KTM road bike to ride on the road that KTM probably wanted to make, but couldn’t…

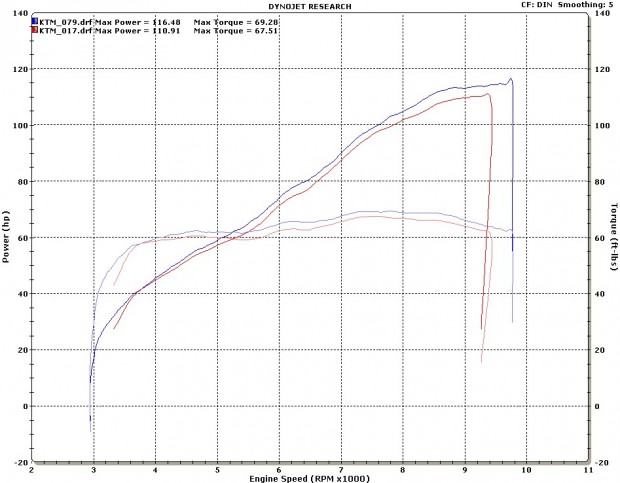

Better driveability were the key words Trev used when he first bought his bike in. We rode the bike when it got here, and just before it left; the on/off throttle low down snatchiness had disappeared and the overall response of the engine is much more urgent. Plus, as an extra bonus one off –shoot of the ECU remap is that fuel economy has gone up by a fair margin, approx. 25 miles per tank, according to the ol’ boy. When we first ran the bike on the Dyno it made 111bhp at the rear wheel, and it left making 116bhp, with a very useful extra couple lb-ft of torque pretty much everywhere.

Check out the power and torque curves below – that’s the bike as it arrived in red, and as it left in blue. It’s amazing what you can do just with computers, eh?